-

Emission Testers

Emission Tester for Petrol- and Gas-Driven Otto Engines

MGT 5

Emission Tester for Gasoline and Gas Powered Otto Engines

-

MGT 5

Wide-range application from a simple, portable standalone unit with internal LED-display up to a sophisticated, networked PC-station with easy, self-explanatory software screen.

- Future oriented concept with variable plug-in modules, e.g.: multi-RPM recording, E-OBD communication unit.

- Interface modules for various connection possibilities to the PC and test lane.

- ASA/Eurosystem-network capabilities.

- NOx-measurement optionally possible.

- Combi-unit for diesel- and gasoline emission testing in connection with MAHA MDO 2 LON (Diesel smoke meter).

- PTB approval of the test equipment under approval number: 18.10/99.25.

- Accuracy class 0 (based on OIML R 99).

- BAR-97 conform.

- Successful in vehicle monitoring in serial application.

-

Diesel Emission Testers(Opacimeter)

-

MDO 2

Diesel Engine Emission Tester (Opacimeter)

-

MDO 2

Not upgradable on emission testing guide 4!

Time saving and trouble-free testing and diagnosis of the smoke emission turbidity using partial current procedure under free acceleration or under engine load.

- Emission tester complies with latest regulations for emission testing (AU)

- All emission testing components (test chamber and probe) made of high quality V2A-steel

- Single or continuous testing

- Full throttle testing for engine adjustment work using a dynamometer

- High-powered test chamber heating

- Menu controlled operator guidance

- Graphic correlation of RPM to turbidity line

- Graphic and digital documentation of the measurement values

- Serial interface RS 232 for connection of chipcard reader, PC and various external data reading units

- Target data carrier-Chipcard (Optional)

- Connectable to the MAHA-test lane and dynamometer

-

-

MDO 2 LON

Diesel Engine Emission Tester (Opacimeter)

-

MDO 2 LON

Emission Tester for Diesel Engines (Opacimeter)

- Future-oriented basis unit, designed for adaption to user's diversifi ed requirements with special accessories (e.g. measurement under load). Modifi ed emission testing standards can easily be adapted to (e.g. E-OBD).

- Presents the concept of an individual, compact unit for stationary as well as mobile application. The same conceptual design of the Otto engine emission tester MGT 5 creates a multi-functional combi-unit for emission testing of gasoline and diesel engines.

- The networking and connection of the MGT 5 to the PC is possibe at any time via RS 232 interface. This can be done without damaging calibration or warranty seals.

- Easy, comfortable operation with clearly structured software.

- Extremely short warm-up phase at unit switch-on.

- The proven sturdy and rugged design means very low maintenace

- Network capabilities (Eurosystem, ASA, Citrix, Giegnet, NCTC...)

- Integration of vehicle target databases (country-specific limit values) (Optional)

- Connection any time to MAHA function and performance dynamometers

-

-

RPM Counter for Emission Testers

RPM VC 2

RPM Counter for Emission Testers

-

RPM VC 2

RPM counter for diesel and petrol engines in cars, trucks and buses

- RPM acquisition via vibration sensor for cars,trucks and buses.

- RPM acquisition via vibration of the on-board voltage.

- RPM display on the unit.

- RPM transmission using loop for trigger clamp to emission testers from other manufactuers .

- RPM transmission using cable to MAHA emission testers.

-

RPM 100

RPM Measurement for Otto Engines & modern Diesel Direct-Injection

-

RPM 100

Speed Measurement for Petrol and Diesel Engines of Cars, Trucks and Motorcycles

- For RPM measurement in the extremely high RPM range.

- Perfect coverage for petrol and diesel engines .

- For static and dynamic speed measurements .

- Self-calibrating and automatic function monitoring .

- Easy mounting due to RPM sensor with clamping tongs.

- Universal, connectable to any exhaust gas tester.

- Unique direct speed measurement.

-

DISPEED 490

RPM Counter for Emission Testers

-

DISPEED 490

Universal Speed Measurement for Petrol and Diesel Engines

- No settings required for engine confi guration.

- Perfect coverage for petrol and diesel engines.

- For static and dynamic speed measurements.

- Self-calibrating and automatic function monitoring.

- Easy mounting due to an integrated permanent magnet.

- Universal, connectable to any exhaust gas tester.

- Unique direct speed measurement.

-

Opazimeter II. Generation MET 6.2

Particle Measurement Device, Continuous Particle Measurement

-

Opazimeter II. Generation MET 6.2

-

Opazimeter II. Generation MET 6.2

The Necessity for Advanced Emission Testing

- Since the introduction on the 1st December 1993 of Emission Testing in its present form, no substantial changes were made to the threshold values in respect of emission limit values. As a supplementary measure, the On Board Diagnosis (OBD) was introduced.

- Considering the technological progress of engines and emission reduction technologies in modern vehicles, the current emission testing regulation is no longer sufficient. It needs to be adjusted in line with current vehicle technology, to ensure that vehicles with high levels of exhaust emissions are detected in the future. Only emission testing that reliably measures the efficiency of all emission components, especially in modern diesel-powered vehicles fitted with a diesel particulate filter, will have an impact on the environment and health.

- The authors of this article, who have significant expertise in emission testing, strongly belief that current emission testing as practiced in Europe has lost its effectiveness. Despite the progress of engine technology, emission limit values were not adapted. As a result, the measurement devices no longer meet the requirements.

- Self-calibrating and automatic function monitoring.

- Especially for modern diesel-powered vehicles equipped with a diesel particulate filter, a conclusive and meaningful assessment is required, that not only tests but that also documents. This would ensure the efficiency of the emission treatment over the entire period the vehicle is used.

- In the meantime the required measuring instruments are available. These devices have demonstrated and proven their thoroughness at a field test of Working Group Emission 2010 (VdTÜV, DEKRA, ZDK, ASA Verband) involving more than 1.000 diesel vehicles in garages and recognised control organisations.

- Their accuracy compared to lab instruments used during engine development, was proven and confirmed by university laboratory tests.

In order to adapt diesel emission testing to the present and future requirements, two steps are necessary:

- 1. First and foremost, the mandatory emission limit values for vehicles need to be adapted to current vehicle technology conditions, as from EURO II. The socalled emission tag values on each vehicle identification plate, of dieselpowered vehicles can be used as a guideline. These values were established during vehicle type approval and documented for the purpose of periodic vehicle inspections.

- 2. Afterwards, there should be a gradual renewal of emission testing devices for diesel emissions, by introducing new instruments with alternative measuring methods capable of measuring the particulate mass concentration of vehicles in a precise and reliable manner. This measuring procedure should be compulsory for modern diesel-powered vehicles, with a transition period of 3 years. To this intent, these new devices could already be certified today as an alternative for current measuring instruments and it would facilitate the eventual compulsory exchange. Prior to being allowed to use the new devices, they should be granted qualification approval (PTB-A) from the relevant German National Metrology Institute.

-

-

MPM-4M

Particle Measurement Device for Mining and Non-Road Applications

-

MPM-4M

Particle Measurement Device for Mining and Non-Road Applications

-

MPM-4M

Particle Measurement Device for Mining and Non-Road Applications

- Real-time measurement of DPM concentration (Total Carbon [TC] or Elemental Carbon [EC]).

- Designed for operation in harsh conditions.

- Advanced microprocessor monitors test from start to finish.

- Controlled sample preconditioning to minimize measurement errors.

- Fully integrated stand-alone instrument.

- Test results displayed immediately at completion of test.

- Large high resolution screen plus visual operator prompts.

- One button operation (with optional remote control for single operator testing).

- Good correlation with laboratory analyzers.

- Suitable for steady-state or transient test measurements.

- Auto-zero before every test.

- One minute field calibration.

- Optional internal NiMh battery-operation (2 h testing per charge).

- Rugged steel case – weight less than 10 lbs.

-

-

Infrared Thermometer

-

Raytek Auto-Pro / Raytek MX 2

Non-contact engine temperature measurement

-

Raytek Auto-Pro / Raytek MX 2

Infrared Thermometer for Non-contact temperature measurement

- Engine temperature

- Heaters/Air conditioners.

- Brakes and bearings.

- Catalytic converters.

- Hydraulic systems.

-

-

-

Testing and Safety Technology

Side Slip Testers

MINC I / MINC II

Side-Slip Tester for CARS up to 3 t axle load (MINC I) and TRUCKS up to 15 t axle load (MINC II)

-

MINC I / MINC II

Side-Slip Tester for CARS up to 3 t axle load (MINC I) and TRUCKS up to 15 t axle load (MINC II)

- Quick inspection with seconds of front and rear axle geometry.

- Depending on tracking, the test plate is pushed to the side and the deviation is displayed.

- Digital display in m/km .

- 3 control lamps .

- Side-slip limit values freely selectable .

- Protocol documentation with Data printer (Minc I D, Minc II D).

-

Shock Absorber & Suspension Testers

SA 2 / FWT 1

Shock absorber tester for CARS and VANS up to 1.1 t axle load (optional 2 t)

-

SA 2 / FWT 1

Shock absorber tester for CARS and VANS up to 1.1 t axle load (optional 2 t)

- Fully automatic inspection of the shock absorber while installed

- Automatic test stand start up after both plates are loaded .

- Inductive electronic distance measurementManual control for noise investigation .

- Evaluation of the measurement results via the data printer in 3 Programs (SA 2 D, FWT 1 D) .

- Display on color screen with measurement values in Mm-Amplitude and Percentage, with Differential display le/ri and graphic display (only Euro-Screen und Euro-System).

- Print out of the measurement values with date, time, company address, graphic (Optional with .

- Euro-Screen, Euro-System) .

- Expandable to a complete test lane (Euro-Screen, Euro-System).

-

MSD 3000

Shock Absorber Tester for Cars and Vans up to 2500 kg

-

MSD 3000

Shock Absorber Tester for Cars and Vans up to 2500 kg

- Analogue display of test results in Teta (Damping measurement unit) percentage on integrated scale in brake tester instrument dial face with left/right brake differential in % (connection to analogue display)

- Display on screen with test results in Teta, with left/right brake diferential and graphic interpretation

- With DIN A4 Printer, print-out of test data with graphics, date and time is possible.

- Fully automatic testing procedure

- Automatic start-up of test stand when both test plates are loaded over 60 kg

- Plate activated to a high resonance via electric motor Maximum amplitude is measured to determine the axle damping.

- Floor unit as self-supporting framework

- Parallelogram guided test plates and therefore no fixed wheel testing point necessary.

- Electro-static powder paint: blue, RAL 5010

-

-

Speedometer Tester

-

TPS

Speedometer Tester for trucks, cars and motorcycles

-

TPS

Shock Absorber Tester for Cars and Vans up to 2500 kg

- Electronic speed measurement with digital display on the handpanel.

- Data printer with printout of the tachometer speed (shown on the tachometer), of the actual speed (shown on the digital display) and of the difference in %. Free programming of the company name, date and time.

- Self-supporting frame with flame sprayed rollers and drive-off system.

-

-

-

Tachograph Tester

-

TCS

EC Tachograph Test Device

-

TCS

EC Tachograph Test Device

Testing of mechanical and electronic EC tachographs and flat tachographs according to § 57 b and § 57 d of the official German Road Regulations

- Tachograph test based on § 57 b and § 57 d of the official German Road Regulations

- Determination of travel RPM; travel pulse count for all mechanical and electronic tachographs

- Programming of FTCO 1319 and MTCO 1324, TVI 2400, prepared for EFAS (Grundig), SmarTach (Actia), DTCO

- Print out and storage of test seals with date, test station number, address, measurement values, chassis number

- Road measurement possible (optional)

-

-

Speed Control

Speed Limit Tester

-

Speed Control

Speed Limiter Tester

- Instantaneous function test of speed limiters and tachographs based on § 57d StVZO

- Prepared for all conventional analog and digital types of tachographs

- Illuminated display with easy-to-use operator guidance

- Portable hand-held device stored in practical plastic case

-

-

SLT 1

Portable hand-terminal for function testing of speed limiter systems based on Guideline 2001/11/EG

-

SLT 1

Speed Limiter Tester

Speed Limiter Tester Portable hand-terminal for function testing of speed limiter systems based on Guideline 2001/11/EG

- Function test of speed limiter in seconds

- Integrated K-value determination

- Portable unit with battery or on-board power supply

- Illuminated LCD display with superior operator guidance

- Adaptable for all standard vehicle tachographs

-

-

Head Light Testers

-

LITE 1 / LITE 1.1

Headlight Tester

-

LITE 1 / LITE 1.1

Headlight Testing Device

- Exact and rapid testing of the headlight image

- Comfortable operation

- High quality, stable construction

- Optimum precision during measurement due to use of an aluminium profile column

- Various country variants are available

- Can be moved on plastic rollers

- Metal case for measuring head moves easily on aluminium profile

- Mirror can be rotated for aligning the machine with the vehicle

- Lenses bundling the incoming headlamp light

- automatic locking of column and case

- Digital luxmeter included as standard equipment

- Various country variants, e.g. also for left-hand traffic

- Particularly suitable for workshop use

- Height-adjustable projection screen with percentage scale

LITE 1

- Particularly suitable for use in inspection areas and testing lanes

- Headlight tester movable on running tracks including column (also available with plastic rollers without rails)

- Extremely robust construction with high quality design

- Mirror can be rotated for aligning the machine with the vehicle

- Easy measured image control from the rear of the machine using deflection mirror

- Large Fresnel lenses for bundling the incoming headlamp light

- Automatic locking of column and case

- Also suitable for left-hand traffic

- Height-adjustable screen with % scale

- Luxmeter for intensity measurement

- Laser alignment unit (option)

LITE 1.1

-

-

LITE 3

Headlight Tester

-

LITE 3

Head Light Tester

- Quick and accurate testing of the headlight setting

- Operator-friendly menu guidance using LCD graphic display

- Measurement recording with CMOS camera technology

- "Stand alone" version with PC connection

- Result evaluation with integrated control electronic

- Easy headlight adjustment with "acoustic setting mode"

-

-

Decelerometer

-

VZM 300

Brake Decelerometer TÜV tested and PTB approved

-

VZM 300

Brake Decelerometer TÜV tested and PTB approved

- Time measurement and documention of vehicle deceleration

- 8 measurement intervals are possible within the max. test time

- Piezo-electronic measurement value recording

- Integrated matrix printer for documentation of the measurement values

- Pedal force meter or pressure converter connection (pneumatic / hydraulic)

- Manual starting and stopping of measurement

- Fully automatic or manual operation

- Digital display of measurement values

- Easy-to-use operational components

- Menu-controlled operator guidance

- Mean value calculation of the braking deceleration

- Calculation of trailer deceleration

- BSU projection (optional)

- Alpha-numeric keypad for input of vehicle data

- Display of vehicle speed and braking distance

- Calculation of the mean full deceleration (Guideline 71/320/EWG)

- Pitch angle compensation: Measurement errors due to vehicle pitch behavior during deceleration automatically compensated for by the integrated gyro-sensor

- Connection of up to 5 sensors (pressure sensor pneumatic/hydraulic/pedal force/traction)

- Exact display of unit position via digital display

- Integrated matrix printer with fourfold speed of earlier models

- Deceleration up to 20 m/s2

- Storage capacity for 14 measurement values with graphic

- Calculation of trailer deceleration without deactivation of tractor brakes

- Battery capacity for approx. 50 measurements (connection to on-board power supply 12/24 V possible)

- Connection possibilities to PC via RS 232 or IrdA interface with delivery protocol for standard spreadsheet software e.g. MS Excel, Lotus

-

-

Play Detectors

-

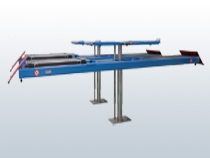

PMS / LMS

Axle- and Joint Play Detector for CARS, VANS, Buses and TRUCKS up to max. 20 t axle load

-

PMS / LMS

Axle- and Joint Play Detector for CARS, VANS, Buses and TRUCKS up to max. 20 t axle load

- Quick inspection of defects and wear and tear on steering components, wheel bearings, springs and suspension

- 1-man-operation

- Checking of the wheel bearing play without lifting the vehicle

- Extremely robust, self-supporting construction

- Two flush floor installed test plates

- Powerful, even movement via hydraulic drive

- Low maintenance

-

-

Brake Fluid Tester

-

BFT 3000

-

BFT 3000

Measuring instrument for quick and accurate testing of brake fluid

- Quick, physical measurement in accordance with boiling point procedure

- Direct measurement at compensation container – no waste disposal problems

- Fully automatic test procedure after brake fluid suck in

- Documentation and print out of the measurement values via PC

- Cable-free operation with exchangable battery or accumulator

-

-

Truck Hand Terminal

-

Truck Hand Terminal

-

Truck Hand Terminal

Test Case for Function Test of Air Brake Systems

- Quick, accurate testing of air brake systems

- Direct pressure display of up to 5 pressure circuits

- Cable-free pressure transmisson via radio pressure sensor

- Function check of trailer interface ISO 11992

- Remote display and operation via PC and PDA

- Graphic plotting and display of measurement value results

- Documentation of measurement values via existing PC

-

-

Radio-Touchscreen

-

FTS 2010

Radio-Touchscreen portable, for simultaneous operation and transmission of measurement screens

-

FTS 2010

Radio-Touchscreen portable, for simultaneous operation and transmission of measurement screens

- Simultaneous remote display of Eurosystem test software via radio transmission

- Direct operation of test device per touchscreen and virtual screen keyboard

- Direct vehicle reception and evaluation

- Function check of trailer interface ISO 11992

- Remote display and operation via PC and PDA

- Graphic plotting and display of measurement value results

- Documentation of measurement values via existing PC

-

-

Closing Force Meter

-

Closing Force Gauge SKM 2

For checking of the closing force on power-operated units

- Rapid and simple checking of the closing force on externally actuated operating doors and closing devices

- Complies with the requirements in accordance with §29 StVZO as well as Guideline 2001/85/EG

- Measurement of effective force (Fe) as well as peak force (Fs)

- Function check of trailer interface ISO 11992

- Digital presentation of the measurement data via illuminated display at handterminal

- Network-independent use via battery-operation

-

Tyre Tread Measurement Device

-

TM 1000

Tire Tread Measurement Device

-

TM 1000

Tire Tread Measurement Device

- Tread depth measurement device integrated into MAHA roller brake testers for passenger cars, light-duty trucks

- Automatic tread depth measurement as part of the brake test

- Test results display via MAHA Eurosystem

- Graphical representation of measured values

-

-

-

Brake Testers

Platform Brake Testers for Cars

-

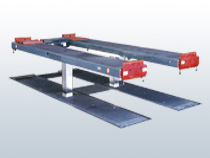

MPP 2

Plate Brake Tester for Cars and Vans up to 4 t axle load

-

MPP 2

Plate Brake Tester for Cars and Vans up to 4 t axle load

- Easy and instantaneous brake test

- Convenient use with large-surface test plates

- Bright LED digital display for measurement value display

- Digital measurement value recording and storage

- Network capabilities with optional PC connection

- Prepared for above-floor or foundation installation

-

-

Roller Brake Testers for Cars

-

MBT 2100

Roller Brake Testers for cars and vans up to 5t

-

MBT 2100

Roller Brake Tester for vehicles to 5t axle load

- Brake tester for cars and vans

- Digital measurement value recording and storage

- Optical differential display (adjustable)

- Including wall attachment

- Plug and play technology for efficient installation and service

- Interface for printer and PC connection

-

-

MBT 3000

Roller Brake Tester for cars, vans and light trucks up to 8 t axle load

-

MBT 3000

Roller Brake Tester for cars, vans and light trucks up to 8 t axle load

- Digital measurement value recording and storage

- From LON to EUROSYSTEM: the modular design

- Patented, correct all-wheel drive testing

- Robust, easy-to-service technology

- Network compatible – ASA network, GIEGNET, MCTC…

-

-

IW 2 LON

Roller Brake Testers for cars and vans up to 4t

-

IW 2 LON

Roller brake tester for cars, vans and light trucks up to 5 t axle load

The IW 2 LON brake tester is used as the basic module for the testing lane. All measurement values can be clearly displayed on the analogue display with braking force difference display and assessed. The automatic test procedure with display enables a rapid diagnosis of the complete vehicle. Particularly suitable for reception and diagnostics lanes; exceeds the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- braking force difference display optic

- lockable main switch

- RS 232 interface connection for printer or PC

- electronic start-up monitoring and roller exiting aid

- single wheel switchover, delayed automatic startup

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- self-supporting, enclosed roller set IW 2 RS 2

- roller surface optionally welded or plastic-coated

- electro-static powder paint: blue, RAL 5010

- TÜV and GS approve

-

-

IW 2 LON ALL-WHEEL

Roller Brake Testers for cars and vans up to 5t

-

IW 2 LON ALL-WHEEL

All-wheel roller brake tester for cars, vans and light trucks up to 5 t axle load

The IW2 LON ALL-WHEEL brake tester with analogue display provides you with high-precision all-wheel drive testing technology in a compact design. With the patented measuring methods, you have the security of being able to correctly test all-wheel drive vehicles without damage. The IW 2 LON ALL-WHEEL has been setting the standard for more than 20 years for testing all-wheel drive vehicles and is keeping pace with modern vehicle technology. The modern, electronic control system also enables the checking of ASR and electronic parking brakes in the course of the brake testing. It is particularly suitable for reception and diagnostics lanes with a high proportion of all-wheel drive vehicles; exceeds the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- braking force difference display optic

- Remote control IFB3

- Pedal force meter

- lockable main switch

- RS 232 interface connection for printer or PC

- electronic start-up monitoring and roller exiting aid

- single wheel switchover, delayed automatic startup

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- all-wheel drive regulation set with electronically controlled roller set

- self-supporting, enclosed roller set IW 2 RS 2

- roller surface optionally welded or plastic-coated

- electro-static powder paint

- TÜV and GS approved

-

-

IW 2 EUROSYTEM

Roller Brake Testers for cars and vans up to 5t

-

IW 2 EUROSYTEM

Roller-Brake Tester for cars and vans up to 5 t axle load

The IW 2 EUROSYSTEM brake tester is the premium tester of the IW 2 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 2 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organisations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with 4WD regulation set and tire tread measurement device, the IW 2 EUROSYSTEM is the ideal diagnostic brake tester. Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

- PC control desk, consisting of stable metal frame with plastic coating and integrated witch cabinet

- compartment for PC and storage surface for keyboard, printer and monitor

- display of all measured values on the PC monitor

- braking force display digital / optic

- PC: Pentium 4, MS Windows XP Professional, DVD drive, keyboard and mouse, 17" monitor

- PC control desk: Colour: plastic side parts in blue, RAL 5010

- electronic start-up monitoring and roller exiting aid

- single wheel switchover, delayed automatic startup

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- self-supporting, enclosed roller set IW 2 RS 2

- roller surface optionally welded or plastic-coated

- electro-static powder paint: blue, RAL 5010

- TÜV and GS approved

-

-

Roller Brake Testers for Trucks

-

MBT 5000

Roller Brake Tester for mobile brake testing on vehicles up to 18 t axle weight

-

MBT 5000

Roller Brake Tester for mobile brake testing on vehicles up to 18 t axle weight

- Compact roller set version for mobile usage

- Low drive-over height of only 150 mm

- Digital measurement value recording and storage

- Durable, service-friendly technology

- Integrated dynamic weighing device (optionally)

-

-

IW 4 LON Classic

-

IW 4 LON Classic

The IW 4 LON CLASSIC roller brake tester is equipped with the classic dual analogue display and an automatically changing display range (0-4 / 0-40 kN). Using the already integrated digital display, information about braking force and shock absorber difference and operator prompting instructions are displayed in a compact way. There is also the possibility of equipping the analogue display with up to four VARIODATA displays for weight, braking pressure, braking intensity and running text for operator prompting.

The tester is particularly suitable for brake diagnostics depending on the weight measurement for low to medium vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus networkcompatible.

- multifunctional analogue display with two dials for displaying measured values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- difference display digital / optic

- Digital measurement value recording and storage

- difference display digital / optic

- lockable main switch

-

-

IW 4 LON Competence

-

IW 4 LON Competence

This tester combines the traditional analogue display with the most up to date electronics. The measured values on two 8 and 40 kN displays are clearly displayed in a large area on the multifunctional analogue display with four dials. An integrated digital display is provided for outputting the braking force and shock absorber difference measured values and instructions for operator prompting. There is also the possibility of equipping the centre of the individual analogue dials with up to four additional VARIODATA displays (e.g. for weight, braking pressure and braking intensity) and the top display area for running text (operator prompting). The wireless remote control REC01 which certainly simplifies vehicle testing for multiple axle vehicles is already included as standard equipment. The tester is particularly suitable for comprehensive brake diagnostics with high vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear) depending on the connected device)

- difference display digital / optic

- two VARIODATA digital displays

- wireless remote control RECO 1

- lockable main switch

- RS 232 interface connection for printer or PC

-

-

IW 4 EUROSYSTEM

-

IW 4 EUROSYSTEM

Roller Brae Tester combined for car and Trucks to 15 t axle load

- The IW 4 EUROSYSTEM brake tester is the premium tester of the IW 4 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 4 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organizations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with all-wheel regulation set, the IW 4 EUROSYSTEM is the ideal diagnostic brake tester.

- Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

-

-

IW 7 LON Classic

-

IW 7 LON Classic

The IW 7 LON CLASSIC roller brake tester is equipped with the classic dual analogue display and an automatically changing display range (0-4 / 0-40 kN). Using the already integrated digital display, information about braking force and shock absorber difference and operator prompting instructions are displayed in a compact way. There is also the possibility of equipping the analogue display with up to four VARIODATA displays for weight, braking pressure, braking intensity and running text for operator prompting.

The tester is particularly suitable for brake diagnostics depending on the weight measurement for low to medium vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus networkcompatible.

- multifunctional analogue display with two dials for displaying measured values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- difference display digital / optic

- lockable main switch

-

-

IW 7 LON Competence

-

IW 7 LON Competence

This tester combines the traditional analogue display with the most up to date electronics. The measured values on two 8 and 40 kN displays are clearly displayed in a large area on the multifunctional analogue display with four dials. An integrated digital display is provided for outputting the braking force and shock absorber difference measured values and instructions for operator prompting. There is also the possibility of equipping the centre of the individual analogue dials with up to four additional VARIODATA displays (e.g. for weight, braking pressure and braking intensity) and the top display area for running text (operator prompting). The wireless remote control REC01 which certainly simplifies vehicle testing for multiple axle vehicles is already included as standard equipment. The tester is particularly suitable for comprehensive brake diagnostics with high vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear) depending on the connected device)

- difference display digital / optic

- two VARIODATA digital displays

- wireless remote control RECO 1

- lockable main switch

- RS 232 interface connection for printer or PC

-

-

IW 7 EUROSYSTEM

Roller Brake Testers for cars and vans up to 5t

-

IW 7 EUROSYSTEM

Roller Brae Tester combined for car and Trucks to 20 t axle load

- The IW 7 EUROSYSTEM brake tester is the premium tester of the IW 7 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 7 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organizations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with all-wheel regulation set, the IW 7 EUROSYSTEM is the ideal diagnostic brake tester.

- Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

-

-

Roller Brake Testers for Special Vehicles with Large Wheel

-

MBT 6000

Roller Brake Tester for Special Vehicles with Large Wheel Diameter

-

MBT 6000

Roller Brake Tester for Special Vehicles with Large Wheel Diameter

- Adapted roller set version for wheel diameter up to 2.2 m

- Prepared for surface or foundation installation

- Digital measurement value recording and storage

- Durable,service-friendly technology

- Fulfills requirements for Main Inspection (MI) and Safety Test (ST)

- Integrated dynamic weighing device (optionally)

-

-

-

Roller Brake Tester for Motorcycles

-

IW 10 PROFI / EUROSYSTEM

Roller Brake Tester for Motorcycles

-

IW 10 PROFI / EUROSYSTEM

Roller BrakeTester for Motorcycles to 2t axle load

- Safe and fast brake testing without driving trial

- Automatic and efficient test procedure with operator guidanceComplete measurement value storage and documentation via EUROSYSTEM

- communication desk

- Accurate weight measurement ensured by clamping device (option)

- Test stand expandable to a complete test lane

-

-

Mobile Roller Brake Tester

-

MBT 2100 / IW2 MOBIL

für PKW und Transporter bis 5 t Achslast

-

MBT 2100 / IW2 MOBIL

for cars and vans up to 5 t axle load

- In the context of environmental conditions, all testers are also suitable for mobile use as above floor version, installation in a trailer or container.

-

-

IW 4 LON MOBIL

Mobile Roller Brake Tester for cars, trucks and vans

-

IW 4 LON MOBIL

Roller Brake Tester Mobile for Cars, Trucks and vans

Description/Standard Equipment Analogue Display:

- Rotatable analogue display on pedestal.

- Folding pedestal mounted on the roller set.

- Display of total brake force and deceleration after the brake test (only possible in conjunction with remote control).

- Program control via LON-Profi PCB.

- Network central control module for LON-network.

- Automatic start control and roller exiting aid.

- Delayed automatic start after entry onto stand.

- Automatic cut-off at selected slip with pointer stop and automatic restart.

- Automatic shut-off after exiting test stand

- Single wheel testing.

- Electronic strain gauge measuring system.

- Lockable main switch.

- Power cable with Cekon plug (lenght ca. 13 m).

- RS 232 interface connection for printer.

- Electro-static powder paint, blue RAL 5010.

- IW 4 mobil RS. No. 1 Brake tester roller set

- Control module for IW 4 roller set .

- Self-supporting and divided roller set

- Roller sets pre-mounted on shafts .

- Welded steel rollers .

- Distance piece sheet

- Ring bolts welded to frame

- Electro-static powder paint, blue RAL 5010

NOTE: Pressure converters cannot be connected Description/Standard Equipment Roller Set:

-

-

-

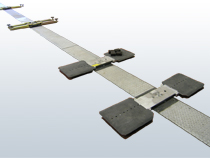

Safety Test Lane

Car-Safety Test Lane

IW 2 LON

Safety Test Lane for cars and vans up to 5t

-

IW 2 LON

Roller brake tester for cars, vans and light trucks up to 5 t axle load

The IW 2 LON brake tester is used as the basic module for the testing lane. All measurement values can be clearly displayed on the analogue display with braking force difference display and assessed. The automatic test procedure with display enables a rapid diagnosis of the complete vehicle. Particularly suitable for reception and diagnostics lanes; exceeds the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- braking force difference display optic

- lockable main switch

- RS 232 interface connection for printer or PC

- electronic start-up monitoring and roller exiting aid

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- roller surface optionally welded or plastic-coated

- single wheel switchover, delayed automatic startup

- electro-static powder paint: blue, RAL 5010

- TÜV and GS approve

-

IW 2 LON ALL-WHEEL

Safety Test Lane for cars and vans up to 5t

-

IW 2 LON ALL- WHEEL

All-wheel roller brake tester for cars, vans and light trucks up to 5 t axle load

The IW2 LON ALL-WHEEL brake tester with analogue display provides you with high-precision all-wheel drive testing technology in a compact design. With the patented measuring methods, you have the security of being able to correctly test all-wheel drive vehicles without damage. The IW 2 LON ALL-WHEEL has been setting the standard for more than 20 years for testing all-wheel drive vehicles and is keeping pace with modern vehicle technology. The modern, electronic control system also enables the checking of ASR and electronic parking brakes in the course of the brake testing. It is particularly suitable for reception and diagnostics lanes with a high proportion of all-wheel drive vehicles; exceeds the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- braking force difference display optic

- braking force difference display optic

- Remote control IFB3

- Pedal force meter

- lockable main switch

- RS 232 interface connection for printer or PC

- electronic start-up monitoring and roller exiting aid

- single wheel switchover, delayed automatic startup

- electro-static powder paint: blue, RAL 5010

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- all-wheel drive regulation set with electronically controlled roller set

- self-supporting, enclosed roller set IW 2 RS 2

- roller surface optionally welded or plastic-coated

- electro-static powder paint

- TÜV and GS approved

Standard equipment

-

IW 2 EUROSYSTEM

Safety Test Lane for cars and vans

-

IW 2 EUROSYSTEM

Roller-Brake Tester for cars and vans up to 5 t axle load

The IW 2 EUROSYSTEM brake tester is the premium tester of the IW 2 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 2 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organisations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with 4WD regulation set and tire tread measurement device, the IW 2 EUROSYSTEM is the ideal diagnostic brake tester. Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

- PC control desk, consisting of stable metal frame with plastic coating and integrated witch cabinet

- compartment for PC and storage surface for keyboard, printer and monitor

- display of all measured values on the PC monitor

- braking force display digital / optic

- PC: Pentium 4, MS Windows XP Professional, DVD drive, keyboard and mouse, 17" monitor

- PC control desk: Colour: plastic side parts in blue, RAL 5010

- electronic start-up monitoring and roller exiting aid

- single wheel switchover, delayed automatic startup

- single wheel switchover, delayed automatic startup

- automatic shut-off after exiting the test stand

- automatic cutoff at selected slip with measured value display and automatic restart

- electronic DMS strain gauge measuring system

- all-wheel drive regulation set with electronically controlled roller set

- self-supporting, enclosed roller set IW 2 RS 2

- roller surface optionally welded or plastic-coated

- electro-static powder paint

- TÜV and GS approved

-

Truck-Safety Test Lane

-

IW 4 LON Classic

-

IW 4 LON Classic

The IW 4 LON CLASSIC roller brake tester is equipped with the classic dual analogue display and an automatically changing display range (0-4 / 0-40 kN). Using the already integrated digital display, information about braking force and shock absorber difference and operator prompting instructions are displayed in a compact way. There is also the possibility of equipping the analogue display with up to four VARIODATA displays for weight, braking pressure, braking intensity and running text for operator prompting.

The tester is particularly suitable for brake diagnostics depending on the weight measurement for low to medium vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus networkcompatible.

- multifunctional analogue display with two dials for displaying measured values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- difference display digital / optic

- Digital measurement value recording and storage

- difference display digital / optic

- lockable main switch

-

-

IW 4 LON Competence

-

IW 4 LON Competence

This tester combines the traditional analogue display with the most up to date electronics. The measured values on two 8 and 40 kN displays are clearly displayed in a large area on the multifunctional analogue display with four dials. An integrated digital display is provided for outputting the braking force and shock absorber difference measured values and instructions for operator prompting. There is also the possibility of equipping the centre of the individual analogue dials with up to four additional VARIODATA displays (e.g. for weight, braking pressure and braking intensity) and the top display area for running text (operator prompting). The wireless remote control REC01 which certainly simplifies vehicle testing for multiple axle vehicles is already included as standard equipment. The tester is particularly suitable for comprehensive brake diagnostics with high vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear) depending on the connected device)

- difference display digital / optic

- two VARIODATA digital displays

- wireless remote control RECO 1

- lockable main switch

- RS 232 interface connection for printer or PC

-

-

IW 4 EUROSYSTEM

-

IW 4 EUROSYSTEM

Roller Brae Tester combined for car and Trucks to 15 t axle load

- The IW 4 EUROSYSTEM brake tester is the premium tester of the IW 4 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 4 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organizations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with all-wheel regulation set, the IW 4 EUROSYSTEM is the ideal diagnostic brake tester.

- Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

-

-

IW 7 LON Classic

-

IW 7 LON Classic

The IW 7 LON CLASSIC roller brake tester is equipped with the classic dual analogue display and an automatically changing display range (0-4 / 0-40 kN). Using the already integrated digital display, information about braking force and shock absorber difference and operator prompting instructions are displayed in a compact way. There is also the possibility of equipping the analogue display with up to four VARIODATA displays for weight, braking pressure, braking intensity and running text for operator prompting.

The tester is particularly suitable for brake diagnostics depending on the weight measurement for low to medium vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus networkcompatible.

- multifunctional analogue display with two dials for displaying measured values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear depending on the connected device)

- difference display digital / optic

- lockable main switch

-

-

IW 7 LON Competence

-

IW 7 LON Competence

This tester combines the traditional analogue display with the most up to date electronics. The measured values on two 8 and 40 kN displays are clearly displayed in a large area on the multifunctional analogue display with four dials. An integrated digital display is provided for outputting the braking force and shock absorber difference measured values and instructions for operator prompting. There is also the possibility of equipping the centre of the individual analogue dials with up to four additional VARIODATA displays (e.g. for weight, braking pressure and braking intensity) and the top display area for running text (operator prompting). The wireless remote control REC01 which certainly simplifies vehicle testing for multiple axle vehicles is already included as standard equipment. The tester is particularly suitable for comprehensive brake diagnostics with high vehicle throughput. The control system meets the requirements for the main inspection, has a PC interface and is thus network-compatible.

- multifunctional analogue display for measurement values of brake tester, shock absorber tester and side slip tester including switching elements (motor protection switch, relay or necessary switchgear) depending on the connected device)

- difference display digital / optic

- two VARIODATA digital displays

- wireless remote control RECO 1

- lockable main switch

- RS 232 interface connection for printer or PC

-

-

IW 7 EUROSYSTEM

-

IW 7 EUROSYSTEM

Roller Brae Tester combined for car and Trucks to 20 t axle load

- The IW 7 EUROSYSTEM brake tester is the premium tester of the IW 7 series. With the EUROSYSTEM testing lane software based on Windows XP and an SQL database, it provides the user with endless possibilities. Whether "only" needed as a brake tester, used as diagnostics reception or as control unit for the workshop processes. The IW 7 EUROSYSTEM is the all-rounder. In combination with other testers, it provides a complete, objective assessment of the vehicle within seconds. Recommended by vehicle manufacturers and tested by international testing organizations in endurance tests, the tester provides a high degree of ergonomics. Upgradeable with all-wheel regulation set, the IW 7 EUROSYSTEM is the ideal diagnostic brake tester.

- Particularly suitable for reception and diagnostics lanes with high vehicle throughput; it exceeds the requirements for the main inspection and is network-compatible.

-

-

Motorcycle-Safety Test Lane

Mobile Test Lane

-

Dynamometer

Single Roller Dynamometer

MSR 500

Single Roller Dynamometer for vehicles up to 2.5 t axle load

-

MSR 500

Single Roller Dynamometer for vehicles up to 2.5 t axle load

- Performance measurement dynamic > 1000 kW

- Measurement range up to 300 km/h

- Suitable for hybrid vehicles in regard to recuperation

- Installation in LPS 3000 foundation possible

- Adjustment of 4-wheel drive version: 2200 - 3200 mm

-

MSR 800 / 830 / 850 / 930 / 1000 / 1050

-

MSR 800 / 830 / 850 / 930 / 1000 / 1050

Description for Model MSR

The MSR is the premium dynamometer of line of function and performance dynamometers from MAHA addressing through its well proven allwheel technology professionals from the area of industrial test rig installation, who intend to perform in-depth measurements under constant load conditions for the purpose of modifying vehicles. This is pure dynamometer technology. The use of electric motors to drive the rollers in combination with high-performance eddy current brakes allows the MSR 1000/1050 to perfectly synchronise the front and the rear axle. Thus vehicles with widely different all-wheel drive systems but also vehicles driven by a single axle can be tested without problems and very efficiently. Moreover, the dynamometer is suited for testing of hybrid vehicles. The MSR is available by way of above floor and under floor models as single or all-wheel dynamometer for any kind of application. This type of dynamometer is especially well-suited for endurance tests and high-power vehicles.

- Top roller performance dynamometer MSR with communication desk and roller set

- Wireless remote control

- One, respectively two roller sets with 700 mm top rollers depending on the model

- Hydraulic roller set adjustment through set of adjustment panels (for all-wheel dynamometer)

- Paintwork powder coating RAL 5010

Scope of Delivery

- Continuous (dynamic) and discrete (static) performance measurement1

- Load simulation1 for constant RPM, speed and traction force

- Graphic and numerical display of wheel power, power loss, engine power and torque

- Projection of engine power in accordance with DIN 70020, EWG 80/1269, ISO 1585, JIS D 1001, SAE J 1349 (optional)

- Test program for speedometer indication

- Driving simulation1

- Possibility of running driving cycles (optional)1

- Analysis of the performance diagrams through cursor function

- 5x zoom function for assessing the curves

- Graphic display of the measured values, comparative measurements in the background

- Stop clock for acceleration measurements between selectable speed marks1

Software

-

Diagnostic Dynamometer

-

FPS 2700 / FPS 5500

Diagnostic Dynamometer for cars and vans up to 5.5t

-

FPS 2700 / FPS 5500

Diagnostic Dynamometer for cars and vans to 5.5 t axle load

- Introduction into vehicle diagnosis under load

- Modular expansion up to complete performance tester

- Engine power determination

- Emission test

- Tachometer test

- Driving cycles (NEFZ, ECE ...)

-

-

Roller Dynamometer, Performance and Function Tester for Cars

LPS 3000

Roller Dynamometer, Performance and Function Tester for Cars up to 2,5t

-

LPS 3000

Dynamometer with micro-processor computer unit for graphic and digital display of the measurement values, with various programs for optimal adaptability for all testing tasks in the workshop.

Description:

Measurement program

- Power measurement at constant RPM,speed,tractive force

- Graphical and numerical display of wheel,drag and engine power and torque

- Background display of three power measurements

- Individual display of performance curves

- Display of speed,RPM and oil temperature during power measurement

- Projection of engine power according to DIN 70020, EEC 80/1269,ISO 1585,JIS D 1001,SAE J 1349 (optional)

- Constant RPM,speed,tractive force

- Road driving simulation

Load simulation with graphical evaluation

- Data collection program for external measurement values: pressure,temperature

- Connection for MAHA emission tester MGT 5 (optional)

- Three additional external values displayable as curves

External measurement data

- Evaluation of performance diagrams via cursor function with numerical display of values at the cursor position

- Graphical display of measured values

- 5x zoom function for evaluation of curves

- Visual display of limit value deviation

- Text input in diagrams and entry field of printout

- Selection of measurement units (kW/PS/BHP......)

- Test program for speedometer display

- Stop watch for acceleration measurement between selectable speed marks

Graphical evaluation for power measurement and load simulation

- Clear color printout (graphics printout optional)

- Performance diagrams of continuous and discrete measurements printable in tabular form;maximum values highlighted;selection of tabular values

Printout

- Storage and loading of performance diagrams

- Data import and export

- Freely programmable load simulation profiles

- Determination of data according to vehicle type

Database

- Driving cycles (optional)

- Language selection

- Radio remote control for dynamometer and cooling fan

Features

-

-

Roller Dynamometer, Performance and Function Tester for Trucks

-

LPS 3000

Roller Dynamometer, Performance and Function Tester for Cars up to 2,5t

-

LPS 3000

Dynamometer with micro-processor computer unit for graphic and digital display of the measurement values, with various programs for optimal adaptability for all testing tasks in the workshop.

Description:

Measurement program

- Power measurement at constant RPM,speed,tractive force

- Graphical and numerical display of wheel,drag and engine power and torque

- Background display of three power measurements

- Individual display of performance curves

- Display of speed,RPM and oil temperature during power measurement

- Projection of engine power according to DIN 70020, EEC 80/1269,ISO 1585,JIS D 1001,SAE J 1349 (optional)

- Constant RPM,speed,tractive force

- Road driving simulation

Load simulation with graphical evaluation

- Data collection program for external measurement values: pressure,temperature

- Connection for MAHA emission tester MGT 5 (optional)

- Three additional external values displayable as curves

External measurement data

- Evaluation of performance diagrams via cursor function with numerical display of values at the cursor position

- Graphical display of measured values

- 5x zoom function for evaluation of curves

- Visual display of limit value deviation

- Text input in diagrams and entry field of printout

- Selection of measurement units (kW/PS/BHP......)

- Test program for speedometer display

- Stop watch for acceleration measurement between selectable speed marks

Graphical evaluation for power measurement and load simulation

- Clear color printout (graphics printout optional)

- Performance diagrams of continuous and discrete measurements printable in tabular form;maximum values highlighted;selection of tabular values

Printout

- Storage and loading of performance diagrams

- Data import and export

- Freely programmable load simulation profiles

- Determination of data according to vehicle type

Database

- Driving cycles (optional)

- Language selection

- Radio remote control for dynamometer and cooling fan

Features

-

-

LPS 3000

LPS 3000

Roller Dynamometer, Performance and Function Tester for Motorcycles up to 1,5t

-

LPS 3000

Dynamometer with micro-processor computer unit for graphic and digital display of the measurement values, with various programs for optimal adaptability for all testing tasks in the workshop.

Description:

Measurement program

- Power measurement at constant RPM,speed,tractive force

- Graphical and numerical display of wheel,drag and engine power and torque

- Background display of three power measurements

- Individual display of performance curves

- Display of speed,RPM and oil temperature during power measurement

- Projection of engine power according to DIN 70020, EEC 80/1269,ISO 1585,JIS D 1001,SAE J 1349 (optional)

- Constant RPM,speed,tractive force

- Road driving simulation

Load simulation with graphical evaluation

- Data collection program for external measurement values: pressure,temperature

- Connection for MAHA emission tester MGT 5 (optional)

- Three additional external values displayable as curves

External measurement data

- Evaluation of performance diagrams via cursor function with numerical display of values at the cursor position

- Graphical display of measured values

- 5x zoom function for evaluation of curves

- Visual display of limit value deviation

- Text input in diagrams and entry field of printout

- Selection of measurement units (kW/PS/BHP......)

- Test program for speedometer display

- Stop watch for acceleration measurement between selectable speed marks

Graphical evaluation for power measurement and load simulation

- Clear color printout (graphics printout optional)

- Performance diagrams of continuous and discrete measurements printable in tabular form;maximum values highlighted;selection of tabular values

Printout

- Storage and loading of performance diagrams

- Data import and export

- Freely programmable load simulation profiles

- Determination of data according to vehicle type

Database

- Driving cycles (optional)

- Language selection

- Radio remote control for dynamometer and cooling fan

Features

-

Function Dynamometer for 2, 3 and 4 Wheel Vehicles

LPS 25

Function Dynamometer for 2, 3 and 4 Wheel Vehicles

-

LPS 25

Function Dynamometer for 2, 3 and 4 Wheel Vehicles

The dynamometers from the LPS 25, MFP 250 lines serve the purpose of testing 2,3 and 4 wheel small vehicles. When the dynamometer simulates the driving resistance, the following data can be recorded and analysed automatically through the operator software: speed, power, distance and measurement time. When connecting a MGT 5 gas tester, also emissions can be recorded.

The measurement data is analysed automatically. The results of the vehicle test can be saved to the database of the dynamometer.

- Dynamometer for small vehicles (with 2 wheels LPS 25, with 3 or 4 wheels LPS 25-3L, MFP 250)

- Painting powder coating RAL 5010

- Simulation of driving resistance through a 10 kW eddy current brake

- In connection with a 4/5 gas tester, model MGT 5, emission measurements under load conditions are possible

Scope of Delivery

- Driving resistance simulation

- Determination of top speed

- Wheel power at test speed

- Display of speed

- Display of distance

- Analysis of the measurement results

- DIN A 4 printout

- Customer and vehicle database

Software

- Connection option for a MAHA 4/5 gas tester MGT 5

External Measurement Data

-

Power Take off Dynamometer for Tractors

LPS MZW 300

Power Take-Off Dynamometer for Tractors (with gear transmission)

-

LPS MZW 300

Dynamometer for tractors with micro-processor controlled computer unit, for digital display of the measurement values

- Measurement of the engine power on the power take off

- Max. power under constant load 220 kW (300 PS)

- Measuring of power, torque, RPM

- Discrete measurement (Automatic RPM selection: Start-, End RPM with intervals and stop time)

- Operator guidance program controlled with LCD-Display

- RPM dependent drag compensation of the eddy current brake

- Test stand control as well as display and print out of the measurement values via hand-held

-

LPS ZW 500

Power Take-Off Dynamometer for Tractors (with gear transmission)

-

LPS ZW 500

Power Take-Off Dynamometer for Tractors

- Measurement of the engine power at the power take off

- Program controlled operator guidance

- Evaluation with radio hand terminal, PC or laptop

- Maximum power input 500 kW

-

Air Cooling Fan

-

AIR 1

General Cooling Fan for cooling of components e.g. with pit power testers

-

AIR 1

Power Take-Off Dynamometer for Tractors

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

General Cooling Fan for cooling of components e.g. with pit power testers

-

-

AIR 2

General Cooling Fan for cooling of components e.g. with pit power testers

-

AIR 2

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

General Cooling Fan for cooling of components e.g. with pit power testers

-

-

AIR 5

High-performance fan for motorcycles and cars

-

AIR 5

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

High-performance fan for motorcycles and cars.

-

-

AIR 7

High-performance air cooling fan especially for trucks.

-

AIR 7

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

High-performance fan for motorcycles and cars.

-

-

AIR 7 Truck

High-performance air cooling fan especially for trucks.

-

AIR 7 Truck

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

High-performance air cooling fan especially for trucks.

-

-

Fans for Component Parts

For additional cooling of turbo, exhaust manifold, oil cooler

-

Fans for Component Parts

The air cooling fan simulates the normal driving wind during performance tests and driving simulation. The air current prevents the engine from overheating and maintains the constant operating temperature encountered during normal driving conditions. The cooling fan creates the ideal ambient temperature conditions for proper measurements.

For additional cooling of turbo, exhaust manifold, oil cooler.

-

-

Lifting Technology

Mobile Column Lifts

MCL

for vans, buses and trucks up to 44t

-

MCL

mobile column lift for Vans, Buses and Trucks up to 44 t

- Electronic control with single and group operation

- Standard delivery expandable to 6 and 8 columns

- Lifting carriage with fi xed wheel lifting forks

- Trapezoidal lifting screw with safety nut

- Automatic synchronization

- Low net weight for easy handling

-

RGE

Mobile Column Lifts for trucks and buses

-

RGE

Mobile Column Lift for trucks and buses

- 5-year warranty on lifting screw and nut

- Automatic synchronization

- Per key click selection of individual posts (Group formation)

- Individual power unit (no master column)

- Low-friction recirculating ball nut and screw (efficiency over 90 %)

- Fuse protection: only 16 amps for 4 columns

- Slim, versatile column design

- Columns weigh only 400 kgs

- Easy to operate

- Long life expectancy

- High safety level ensured by independent locking device

- Manual lowering function

- Quick and easy interconnection of columns

- Electronic measurement by inductive sensors

-

RGA

batteriebetrieben, für LKWs und Busse

-

RGA

Wheel Engaging Lift, battery-powered, for Trucks and Buses

- Four single mobile columns incl. splash-proof control box and operating unit at each column

- Hydraulic dolly firmly bolted to each column

- Lifting carriage with fixed wheel engaging forks

- Automatic synchronisation as standard

- Powered through four batteries, 12 V each

- Electronic synchronisation and safety monitoring through wireless link

- Drive unit with worm gear motor at the top and low-wear and low-maintenance hardened precision screw with recirculating ball nut (efficiency over 90 %)

- Safety locking device independent of drive and screw

- Emergency lowering function, for mechanical lowering in the event of a power failure

- 5 year screw operation warranty, very long service life

- Limit stop, safety monitoring and displacement measurement through non-contact inductive sensors

- Selection of single columns (grouping) by keypress

- Non-contact RPM sensing, bottom limit switching and nut monitoring through proximity switch, upper limit switching is software controlled

- EC type approval (CE)

Supplied Equipment

Description

-

-

Two Post Lifts

ECON III 3.0

for cars and vans up to 3.0 t load capacity

-

ECON III 3.0

for cars and vans up to 3.0 t gross weight

- Permanent self-monitoring of all safety functions

- Short raising and lowering time

- Universal support arms with large extension length, for mini cars and for vans

- Short support arms with 180° swivel range

- 5-year warranty on lifting screw and nut (HWR system)

-

ECON III 3.5

for cars and vans up to 3.5 t gross weight

-

ECON III 3.0

for cars and vansup to 3.5 t gross weight

- Permanent self-monitoring of all safety functions

- Short raising and lowering time

- Universal support arms with large extension length, for mini cars and for vans

- Short support arms with 180° swivel range

- 5-year warranty on lifting screw and nut (HWR system)

-

ECON III 4.0

for cars and vans up to 4.0 t gross weight

-

ECON III 4.0

for cars and vansup to 3.5 t gross weight

- Permanent self-monitoring of all safety functions

- Short raising and lowering time

- Universal support arms with large extension length, for mini cars and for vans with long wheelbase

- Short support arms with 180° swivel range

- 5-year warranty on lifting screw and nut (HWR system)

-

ECON III 5.0

for cars and vans up to 5t load capacity

-

ECON III 5.0

for passenger cars and vans up to 5.0 t gross weight

- Permanent self-monitoring of all safety functions

- Comes standard with 4 double telescopic support arms

- with large extension range, for mini cars and for vans

- with long wheelbase

- Rugged support arms with low bottom clearance

- Proven MAHA plug-in system is part of standard delivery

- Ergonomic operation via foil keypad

-

BELTLIFT 3.0

Electro-hydraulic, for cars and vans up to 3.0 t gross weight

-

BELTLIFT 3.0

Electro-hydraulic, for cars and vans up to 3.0 t gross weight

- Very short post height (2651 mm), cylinder does not extend beyond post, lift can be erected in low-ceiling rooms

- Function based on the "Forklift principle" with flat belts

- Maintenance-free and flat belt with high life durability

- Additional safety band for the control "Flat belt breakage"

- Electro-magnetic safety catch for security at leakage

- Free-standing post design, no bothersome cross support between the posts

-

Four Post Lifts

-

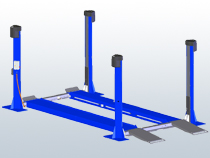

CARLIFT II

Four Post Lift electro-hydraulic, for cars and vans up to 5 t overall weight

-

CARLIFT II

Four Post Lift electro-hydraulic, for cars and vans up to 5 t overall weight

- Suitable for service, repair and wheel alignment

- Reinforced runways for greater flexural strength

- Generous column clearance

- Rugged, long-life construction

- Automatic cable failure protection

- Mechanical wheel alignment locks with finely adjustable lock ladders included as standard

- No compressed air required for lift operation (CARLIFT II 3.5 / 4.0 / 4.0 W)

-

-

TRUCKLIFT 8/10

Four Post Lift up to 8 t or 10 t load capacity

-

TRUCKLIFT 8/10

Four Post Lift up to 8 t or 10 t load capacity

- Base frame-free columm construction with 4 electronically regulated electric motors

- Fully automatic permanent lubrication for spindle and nut

- Manually adjustable left driving platform

- 230 volt socket on the operational unit

- Wear- and maintenance-free synthetic support nuts

- Carriage guidance in the columns with maintenance-free roller bearings

- Electro-static powder paint coating process for excellent corrosion protection

- Electronic micro-processor control with automatic monitoring of safety features: Synchronization control . Phase failure . Belt breakage Support nut wear and tear. Motor overload, Automatic stop at upper/lower position and at obstacle collision

- Powder paint coating black/blue RAL 5010

- CE conformity

-

-

Taktstand

for cars and vans up to 5 t

-

Taktstand

4-Column Platform for cars and vans up to 5 t load capacity

- Electro-mechanical spindle drive via toothead belt

- Wear and maintenance free synthetic support nut

- Fully automatic permanent lubrication

- Electronic microprocessor control with self-monitoring of all safety features

- Hydraulically extendable wheal placement pads

-

-

-

One Cylinder Lifts

-

with swivel arm supports

-

One cylinder lifting device with swivel arm supports

- One cylinder swivel arm lifting device with rubber support plate

- Fully accessible in the sill and motor region

- Height adjustment of support plate using thread and connector system

- Automatic support arm stop at ground level

-

-

with flat supports

-

One cylinder lifting devices with flat supports

- One cylinder flat support bridge with rubber support

- Robust lifting device with rigid components

- Asymmetrical pull-outs with large lateral adjustability and low crossing height

- Galvanised support

-

-

with wheel/sill supports

-

Ein-Stempel-Hebebühne with wheel/sill supports

- One cylinder lifting device with wheel/sill support

- Particularly suitable for body work

- Completely accessible sill area

- Galvanised support

-

-

-

Two Cylinder Lifts

-

with flat supports

-

Two cylinder lifting device with flat supports

- Flat support bridge with pull-outs and rubber pad

- Asymmetrical pull-outs with large lateral adjustment range and tall approach height

- Galvanised support

-

-